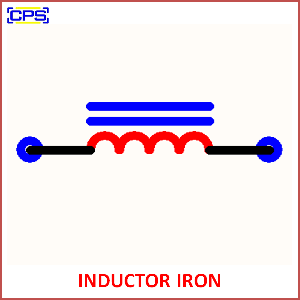

An inductor iron refers to an inductor that uses a core made of iron or iron-based materials. The core material significantly enhances the inductor’s ability to store magnetic energy and increase inductance. Iron cores are commonly used in inductors to improve performance, especially in low-frequency applications.

Key Features of an Iron-Core Inductor:

- Core Material:

- Made of iron or iron alloys, which have high magnetic permeability. This allows the inductor to store more magnetic energy in the core compared to air-core inductors.

- Inductance:

- The inductance is higher in iron-core inductors due to the magnetic properties of iron, which concentrate the magnetic field within the core and reduce energy losses.

- Applications:

- Iron-core inductors are widely used in transformers, chokes, and filters in power supply systems, audio equipment, and radio frequency applications.

Advantages:

- Higher Inductance: Iron cores provide higher inductance values in a smaller physical size.

- Increased Efficiency: More efficient at converting electrical energy into magnetic energy.

Disadvantages:

- Core Saturation: Iron cores can saturate at higher currents, reducing their effectiveness at higher power levels.

- Losses: Iron-core inductors can experience core losses, including hysteresis and eddy current losses, at higher frequencies.

Applications:

- Power Supplies: Used in voltage regulation and filtering.

- Transformers: Essential in step-up or step-down voltage conversion.

- Signal Filtering: Used to block high-frequency noise in electronic circuits.

Iron-core inductors are valuable components in electronic circuits, offering enhanced performance in energy storage and signal processing.