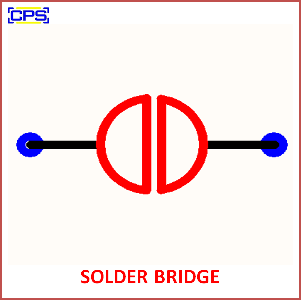

A Solder Bridge is an unintended or deliberate electrical connection created between two or more adjacent conductive traces or pads on a circuit board using solder. While typically considered a fault in PCB assembly, solder bridges can also be intentionally used as part of circuit design for shorting specific connections.

Key Features of a Solder Bridge

- Unintentional Solder Bridge:

- Occurs due to excessive solder application, poor soldering technique, or insufficient spacing between conductive traces or pads.

- Can cause short circuits, leading to malfunction or damage to the circuit.

- Intentional Solder Bridge:

- Used in PCB design for programming, configuration, or testing purposes, allowing easy connection or disconnection of circuits by soldering or desoldering the bridge.

Applications of Intentional Solder Bridges:

- Circuit Configuration:

- Allows selection between different modes or features in a circuit.

- Programming and Debugging:

- Enables temporary connections during device programming or testing.

- Cost Reduction:

- Eliminates the need for additional components like jumpers or switches in specific cases.

Advantages:

- Intentional Bridges:

- Cost-effective and simple to implement for configuration and testing.

- Unintentional Bridges:

- Can serve as a diagnostic marker for manufacturing defects.

Disadvantages:

- Unintentional solder bridges can lead to:

- Short circuits and potential damage to components.

- Increased troubleshooting and repair time.

- Degraded reliability in the final product.

Prevention of Unintentional Solder Bridges:

- PCB Design:

- Ensure proper spacing between conductive traces and pads.

- Soldering Technique:

- Use the correct amount of solder and a steady hand or automated system.

- Inspection:

- Perform visual or automated inspection (e.g., AOI) after soldering.